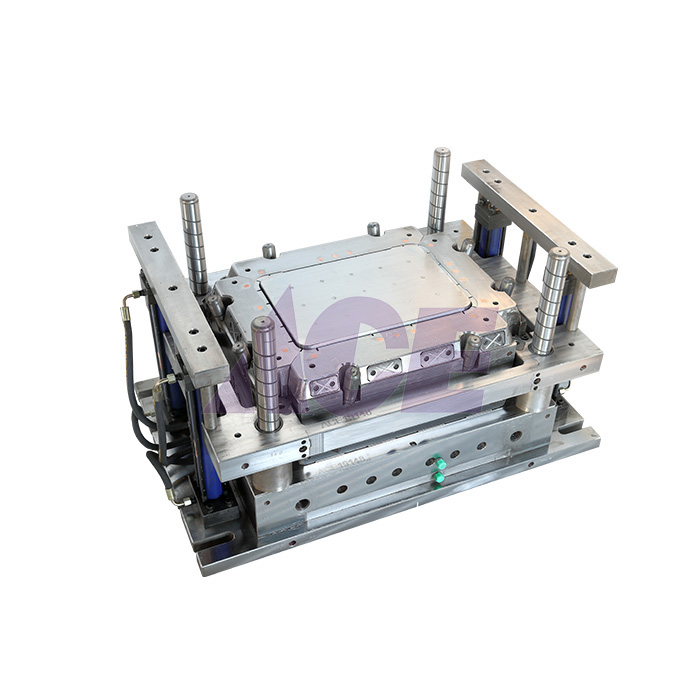

Crate mould

ACE MOULD is the leading plastic crate mould manufacturer in China. We supply various kinds of crate mould for our home and overseas customers with 15 years' experiences, almost 100 sets crate moulds every year. Our crate mould is with reasonable structure, reliable operation, easy molding process control, crate quality assurance, short time delivery, and competitive price to meet our customers' requirements.

Plastic crate mould we made:

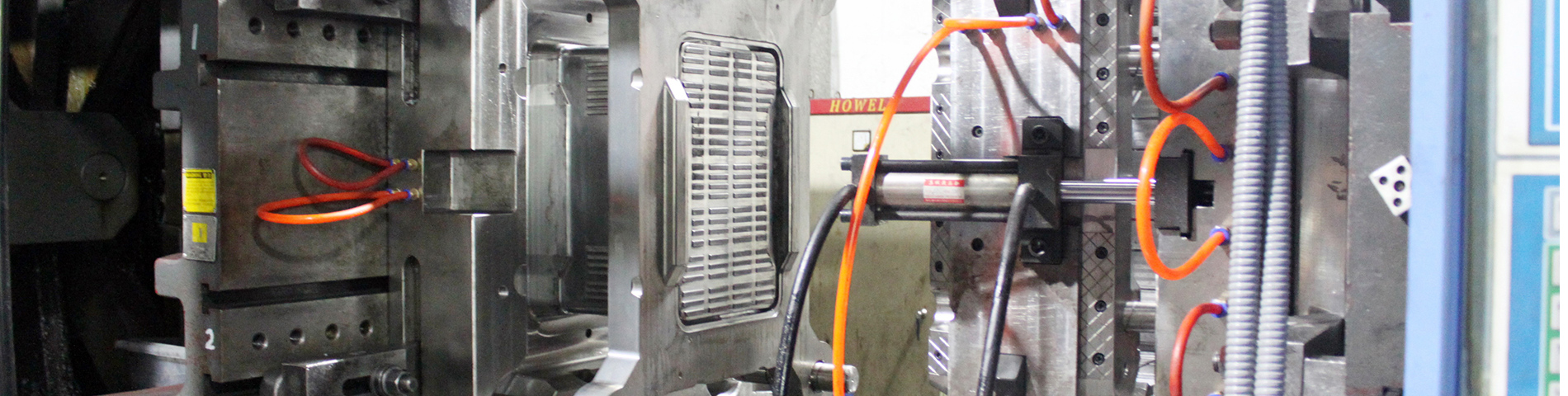

1, Choose the correct steel for mould core & cavity for different kinds of crates. Strictly control the hardness of each part's steel.

2, Use high precise machine to process the slider guiding system and stripper plate part for the crate mould. Rough machining and hand working is not acceptable.

3, Use hot runner system technology to improve the quality of the plastic parts, reduce production costs and save time.

4, Use exhaust system at the handle area is very important, if mould exhaust system at the handle area is not good, it will leave a visible weld, then the crate will be very easy to damage.

5, Use good cooling system can make with the short cycle time.

The maintenance of the crate mould before production

Clean the mould surface for the oil, rust, check mould cooling hole for foreign material.

Check the sprue if there is residual material.

Check the fixed mould plate and confirm if the screw clamp is tightened.

After crate mould fixed on the injection moulding machine, injection operation should be carried out first.