We are committed to supply high-quality products and satisfactory service to customers through innovation, customer focused and continuous improvement.

ACE mould is a professional team with spirit and passion. As we are young we dare to make innovation, as we are professional we are brave to pursue advancement. ACE mould engineers have very rich experience in designing and developing of mould making.Their principle is 'A good product's design is the key', so engineers pay special attention to the mould designing. Try aborative design to extend the service life of mould and reduce maintenance.

Clients can provide the 2D or 3D drawings in DXF, DWG, PRT, IGS, STP format or just send us the sample. We will scan the sample, make product 3D, then design the mould drawing after getting the clients' comments. We can use Unigraphics, SolidWorks, AutoCAD and Pro/ENGINEER for mould-making.

ACE mould is a professional team with spirit and passion. As we are young we dare to make innovation, as we are professional we are brave to pursue advancement. ACE mould engineers have very rich experience in designing and developing of mould making.Their principle is 'A good product's design is the key', so engineers pay special attention to the mould designing. Try aborative design to extend the service life of mould and reduce maintenance.

Clients can provide the 2D or 3D drawings in DXF, DWG, PRT, IGS, STP format or just send us the sample. We will scan the sample, make product 3D, then design the mould drawing after getting the clients' comments. We can use Unigraphics, SolidWorks, AutoCAD and Pro/ENGINEER for mould-making.

Our company

Our work philosophy is oriented to generating added value by assisting the projects integrally in the plastics industry.

Our mission is to be with the customer all the way with the objective to assure thorough communication, coordination and achievement of the targets established… how?

By means of a company structure conceived to provide with the best service to achieve the technical, financial and feasibility expectations set by our customers.

Conceptual design

We provide state-of-the-art approaches and customer focused concepts that give the product a strategic position in the market.

We bring together the current trends with the leading edge ones when it comes to materials and methods.

We match the colors and textures with the geometries to achieve homogeneous and eye-catching results.

Development of pieces

We create complex part designs and provide technical solutions that optimize the tool manufacturing activities.

We stress out the importance of the input coming from the experience with the purpose to reach a functional and feasible molded product.

We use methods of base development resting on the software Unigraphics to create the mathematical models of the pieces, also we use inverse engineering in the cases that are needed taking as item a physical model of the product.

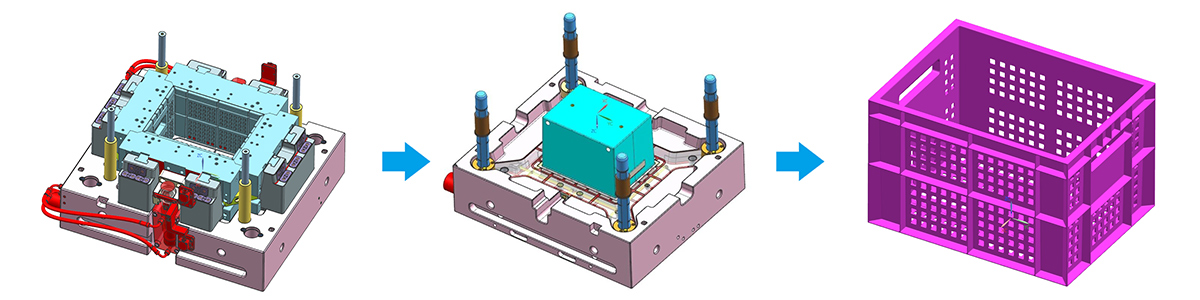

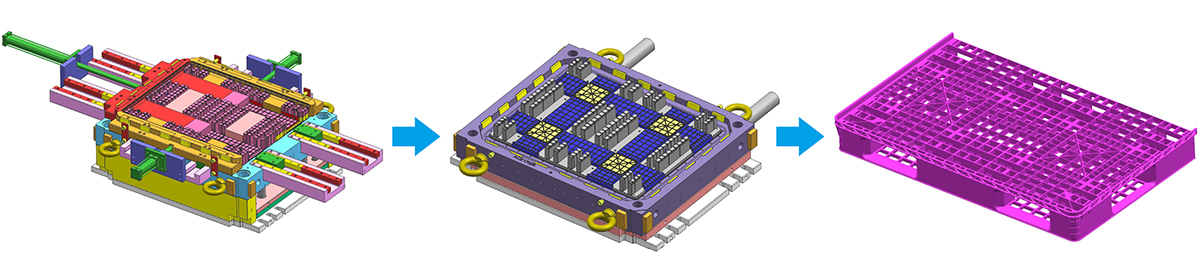

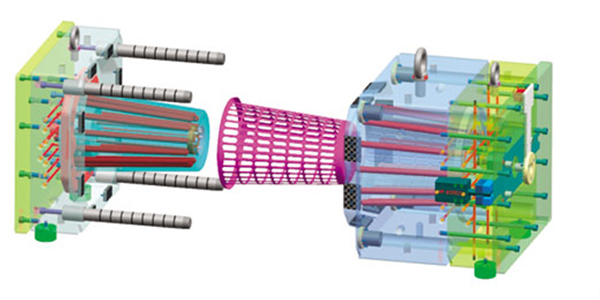

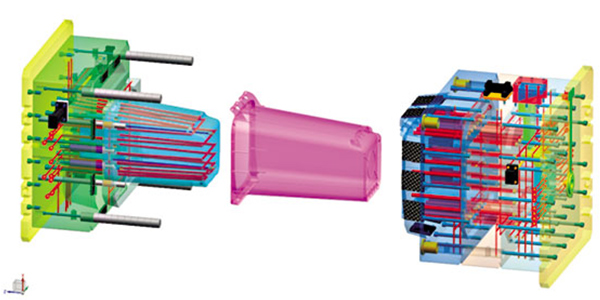

Design of moulds

We provide innovative technical solutions into the tool design and implement them by means of a highly skilled team and state-of-the-art IT resources.

Due to the wide range of products for which we design tools, we managed to bring together different backgrounds and create a common foundation based on the very best from each of those, achieving tools with an outstanding quality and performance.

Mould construction

The current market competitiveness is forcing the enterprises to keep a very close eye on the investments, and considering the relevant expense proportion that the injection molds represent in the plastic sector, we can offer a product that fits both the financial and the technical expectations of our customers.