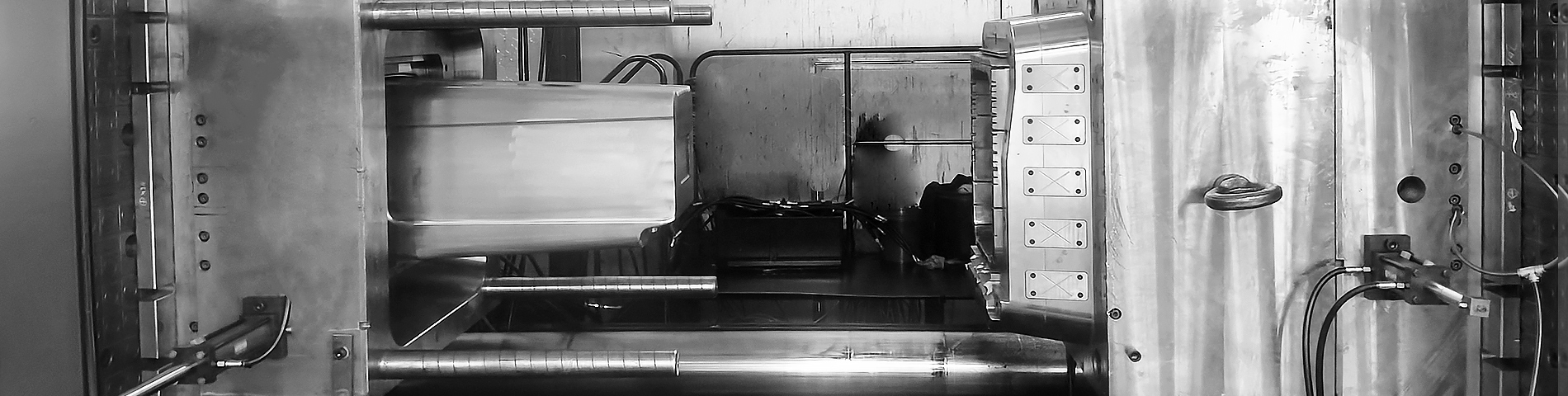

Bathtub mold

The plastic bathtub molds for injection molding to make the baby bathtubs and big tubs. This plastic bathtub mold use the hot runner system from the bottom of product enter into the plastic material.

We use PP material for the baby bathtub as usual. If the thickness of bathtub is quite thin, we must use the high melt index of plastic material for production.

According to our experience, some clients from South America like to make the wall thickness quite thin in order to reduce the plastic material cost.

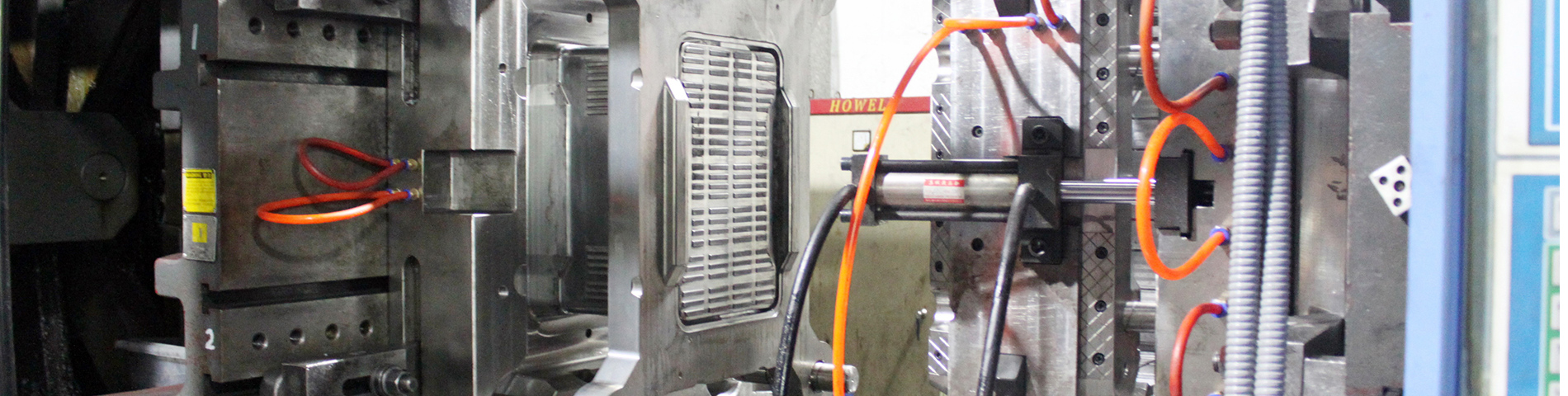

The style on the photo is air vent for ejection, but we also can use ejection pins or stripper plate for demould.

Baby bath mold

Baby bathtub mold

Basin mould

Commodity mould

Tub mould

Household mold

Houseware mold

wash basin mold

Bathtubs to be injected moulding must be very carefully designed to facilitate the moulding process and the demould system.

If the mold is machined with decenter or any problem, the mold must need to machine one time more and the cost will be increased double, so our factory always use high speed engraving machine to ensure the high-precision, high-quality products.

The demould system is quite important, we must choose the best way to fit the style.

Our 15 years working experience engineer and tool makers will use their special design on the air vent as well, since the PP material is always with air exhaust problem.

How does the plastic bathtub mold work?

The plastic bathtub mold cannot work it by itself for production, it must work together with the injection molding machines.

We choose the reasonable machine at first, such as 650T or 780 injection machine.

Then we fed the plastic PP material granules into a heated barrel via a hopper, melted using heater bands and the frictional action of a reciprocating screw barrel.

The plastic is injected through the nozzle into bathtub mould cavity when the mold is closed on the machine, the liquid hardens or sets inside the mold, adopting its shape.

At last, open the mold after the parts cool down and take it out.

The mold action as below after install on the injection molding machine:

1. Close the mold;

2. Inject plastic material into the mold cavity via nozzle;

3. Keep the mold closed until the plastic parts cold down and can be ejected;

4, Open the mold;

5. Push the molding parts come out the mold and fall down;

6. Close the mold for next shot.

If necessary, the injection molding machine can extend the mold opening time to prepare for the next (injection) cycle.